Adjustable Parameters: The cream jar automatic assembly machine boasts a highly intuitive interface, empowering operators to finely tune critical parameters. Filling speed, pressure, and nozzle size can all be meticulously adjusted, enabling precise control over the dispensing process. This level of customization is indispensable when accommodating creams with varying viscosities. Operators can effortlessly calibrate these parameters to match the specific characteristics of each cream formulation, ensuring consistent and accurate filling regardless of viscosity.

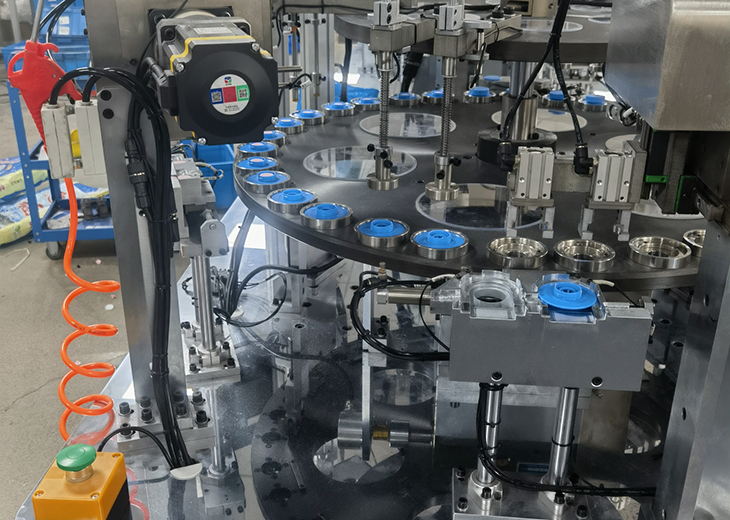

Precision Control Systems: At the heart of the machine lies an advanced control system engineered to maintain unparalleled precision throughout the assembly process. Leveraging cutting-edge algorithms and an array of sensors, this system continuously monitors key variables such as flow rate, pressure, and viscosity in real-time. By analyzing this data on the fly, the control system orchestrates dynamic adjustments to the machine's operation, compensating for any fluctuations in viscosity with lightning-fast precision. This adaptive approach guarantees that every cream jar is filled with the utmost accuracy, regardless of the viscosity of the cream being dispensed.

Sensors and Feedback Mechanisms: Embedded within the machine are state-of-the-art sensors specifically designed to detect variations in cream viscosity. These sensors act as the frontline guardians of quality, swiftly identifying any deviations caused by factors like temperature changes or alterations in cream composition. Upon detection, the feedback mechanism springs into action, transmitting this invaluable data to the control system in real-time. Armed with this insight, the control system orchestrates immediate adjustments to critical parameters, ensuring that the assembly process remains finely tuned and consistently delivers flawless results across all viscosity levels.

Variable Speeds: Flexibility is the hallmark of the cream jar assembly machine's design, exemplified by its variable speed controls. Operators wield the power to finely tune the speed of conveyors, filling pumps, and other pivotal components to suit the viscosity of the cream being processed. Whether dealing with thick, luxurious creams or lighter, fluid formulations, operators can effortlessly adjust the machine's speed to optimize efficiency and maintain impeccable accuracy throughout the assembly process. This dynamic adaptability ensures that production remains seamlessly efficient, regardless of the viscosity challenges posed by different cream formulations.

Adaptable Components: Versatility is key when it comes to handling creams with varying viscosities, and the cream jar assembly machine rises to the occasion with its array of adaptable components. Interchangeable filling nozzles and valves stand as testament to the machine's unparalleled versatility, offering operators the freedom to tailor the assembly process to suit the unique characteristics of each cream formulation. Whether it's a wide nozzle for thick, rich creams or a finer nozzle for more fluid consistencies, the machine's modular design ensures effortless adaptation, guaranteeing optimal filling performance across the entire spectrum of cream viscosities.

Cleaning and Maintenance: Behind every successful operation lies a robust regimen of cleaning and maintenance, and the cream jar assembly machine is no exception. By implementing regular maintenance tasks such as lubrication and calibration, operators ensure that the machine operates at peak efficiency, regardless of the viscosity challenges posed by different cream formulations. This proactive approach to maintenance not only enhances performance but also extends the machine's lifespan, safeguarding long-term productivity and profitability.

Cream Jar Automatic Assembly Machine

русский

русский Español

Español عربى

عربى